Features and main applications of cutting submersible sewage pumps

Main Features of Cutting submersible sewage pump :

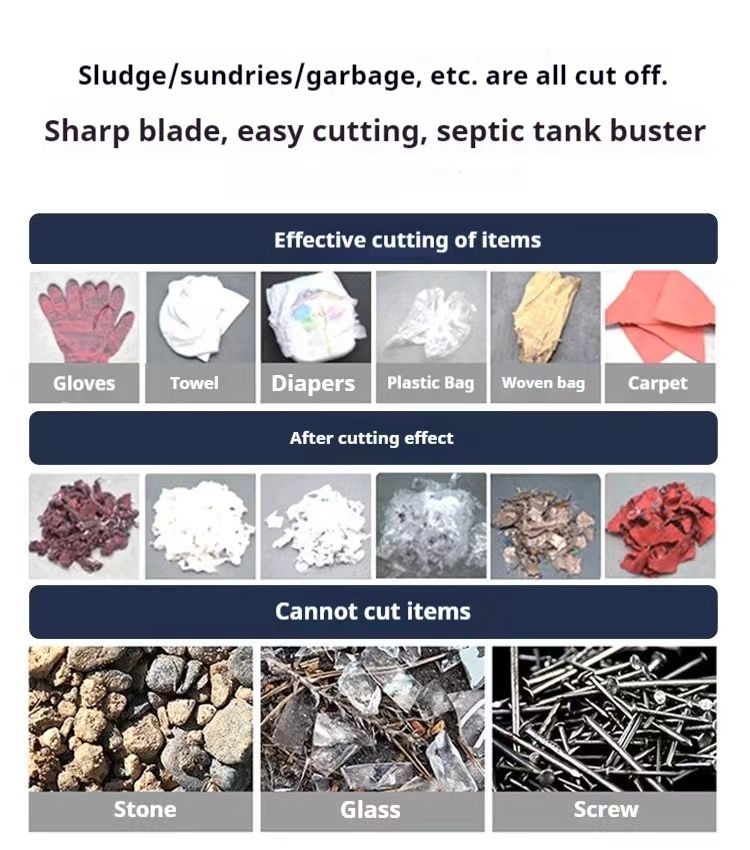

1. Utilizes advanced technology, boasting strong sewage discharge capacity, clogging-free operation,

and effectively handling solid particles with a diameter of φ30-φ80 mm.

2. The tearing mechanism effectively tears and cuts fibrous materials for smooth discharge, eliminating

the need for a filter screen on the pump.

3. Rational design with a low-power motor, resulting in significant energy savings.

4. Utilizes a new material mechanical seal, enabling the pump to operate safely and continuously for over 8000 hours.

5. Compact structure, easy to move, and simple to install, reducing project costs and eliminating the need for a pump house.

6. Can be used across the entire head range without overloading the motor.

7. The float switch automatically controls the pump's start and stop based on required water level changes,

requiring no manual supervision.

8. The dual-guide rail automatic installation system greatly facilitates installation and maintenance, eliminating

the need for personnel to enter and exit the sewage pit.

9. Equipped with a fully automatic protection control box, the product is effectively protected against leakage,

water leakage, and overload, thus improving its safety and reliability.

Main applications of Cutting submersible sewage pump:

1. Discharge of heavily polluted wastewater from factories and commercial establishments

2. Sewage discharge from hospitals and hotels

3. Discharge systems of urban sewage treatment plants

4. Municipal engineering projects and construction sites

5. Sewage drainage systems in residential areas

6. Auxiliary equipment for exploration and mining

7. Drainage stations for civil defense systems

8. Rural biogas digesters and farmland irrigation

Post time:2026-01-06