MAAG gear pumps Booster pumps and polymer metering pumps for industrial applications thermorex TR/TB/TP

MAAG gear pumps Booster pumps and polymer metering pumps for industrial applications thermorex TR/TB/TP

Polymer processing requires intensifier pumps and polymer metering pumps to gently process both high-viscosity

and low-viscosity plastic melts through the polymer processing system.

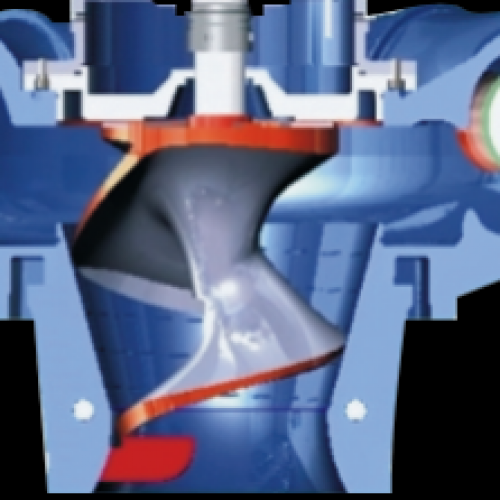

The specially designed low-compression gear teeth allow the x6-stage THERMOREX transfer pump, intensifier pump,

or metering gear pump to achieve high pressures and low shear stress. They deliver a constant, precise flow rate of

plastic melt even at high discharge pressures. These intensifier pumps are also suitable for low-viscosity products

such as prepolymers, where previous polymer pumps have reached their performance limits. Furthermore, their

high efficiency and long service life increase production plant capacity.

Suitable for

Compounding

Masterbatch

Recycling

Polymer Production

Your ideal partner, innovative in traditional technology to meet the demands of chemical and industrial processes, demands tailor-made solutions and adaptable products. With pumps manufactured from modular components, Maag has found a way to combine attractive price points with short delivery times. Achieving this level of performance exemplifies the progressive thinking that has characterized our corporate culture since its inception. Another benefit of modularity is that all components are field-proven for reliable, long-term operation. Our global service network provides expert technical advice to ensure uninterrupted machine operation. Whatever your process requirements, whether involving pressure, temperature, or viscosity, a Maag pump system is the right choice.

MAAG gear pumps Booster pumps and polymer metering pumps for industrial applications thermorex TR/TB/TP Advantages

Improved wear resistance

25% lower energy consumption

12% higher volumetric efficiency

10% lower temperature rise

40% better bearing heat transfer

30% lower vibration

50%

MAAG gear pumps Booster pumps and polymer metering pumps for industrial applications thermorex TR/TB/TP

Typical pumpable media (EN)

Cellulose acetate

Elastomers

Epoxy resins

Phenolic resins

Polyacrylonitrile

Polyamides

Polycarbonates

Polybutylene terephthalate

Polyethylene terephthalate

Polymethyl methacrylate

Polypropylene

Polystyrene (including ABS, EPS)

Polysulfones

Silicone resins

Styrene-butadiene latex

Other

Paints and varnishes

Waxes and paraffins

Mineral oils and fats

Fuels

Petrochemicals

Lubricants

MAAG gear pumps Booster pumps and polymer metering pumps for industrial applications thermorex TR/TB/TP Technical Data

Speed [rpm] Max. 100

Torque (Nm) Max. 600,000

Differential pressure [bar] Max. 320

Viscosity (Pas) Max. 20,000, TO: Max. 60

Temperature °C 350

Output l/min Max. 900

Housing: Alloy/Carbon Steel - Other materials available upon request

Gear Shaft: Nitrided Steel/Tool Steel

Bearings: Tool Steel/AlBr/Special Materials

Shaft Seal: Threaded Seal, Vislip®, Double Mechanical Seal with Barrier System

Pump Heating: * Oil Heating: Maximum Temperature 350°C; Maximum Pressure 15 Bar

Saturated or Superheated Steam: Maximum Pressure 40 Bar

Installation: Thermorex® gear pumps can be flanged to the production line or directly connected to a mixer, compounder, or extruder.