MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX

MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX

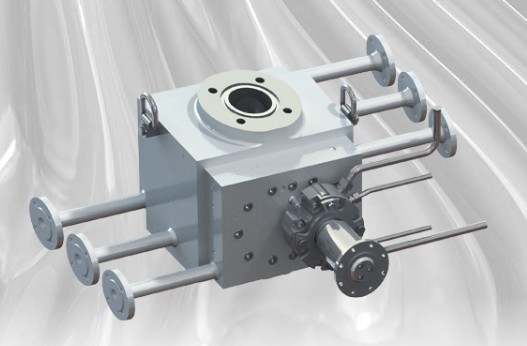

MAAG has launched the vacorex⁶ six-stage polymer extraction gear pump. The vacorex⁶ enables modern polymer production processes, which require polymer pumps capable of discharging at high pressure, even with low fill and high vacuum conditions in the reactor/devolatilization vessel.

MAAG's vacorex⁶ polymer extraction pumps can handle a wide range of polymer grades without compromising quality.

Reliable and maintenance-free, vacorex⁶ polymer gear pumps are designed to withstand the rigors of years of operation,

making them the ideal solution for these applications.

Suitable for

Polymer production

Your ideal partner, innovative in traditional technology to meet the demands of chemical and industrial processes, demands tailor-made solutions and adaptable products. With pumps manufactured from modular components, Maag has found a way to combine attractive price points with short delivery times. Achieving this level of performance exemplifies the progressive thinking that has characterized our corporate culture since its inception. Another benefit of modularity is that all components are field-proven for reliable, long-term operation. Our global service network provides expert technical advice to ensure uninterrupted machine operation. Whatever your process requirements, whether involving pressure, temperature, or viscosity, a Maag pump system is the right choice.

MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX Advantages

Compared to conventional pumps of the same size, flow rates are increased by up to 40%, pressure by 28%,

and flow by 11%. Bearing heat transfer is improved by 30%. Optimized geometry and a larger inlet port

increase the pump's volumetric efficiency by 15%. Volumetric efficiency is increased by 8%, and energy

consumption is reduced by 10%.

MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX Typical Pumping Media (EN):

Polyester/polybutylene terephthalate

Polyamide, polycarbonate

Cellulose acetate, polyacrylonitrile

Silicone/motor oil additives

Styrene-butadiene latex/epoxy resin

Phenolic resin, polymethyl methacrylate

Polystyrene (including ABS, EPS)

Polysulfone

Elastomers/polyolefins

MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX Other

Paints and varnishes

Waxes and paraffins

Mineral oils and fats

Fuels

Petrochemicals

Lubricants

MAAG Gear Pumps Polymer Extraction Pumps for the Polymer Processing Industry - vacorex VX Technical Data

Speed [rpm] max. 150

Differential pressure [bar] – 320

Viscosity (Pascals) max. 20,000

Temperature °C max. 350

Output l/min max. 2,700

Casing: Alloy/carbon steel - Other materials available upon request. Gear shaft: Nitrided steel/tool steel. Shaft

seal: * Standard: Vispac with standard barrier system and adjustable throttle screw. * Optional: Threaded seal,

Vislip double mechanical seal with barrier system. Pump heating: Hot oil or steam: Design conditions: 25 bar/350°C.

Mounting: For vertical, direct mounting on the vessel.

-2-140-Vertical-Multi-Stage-Centrifugal-Pump.447.1.jpg)